Your shopping cart is empty.

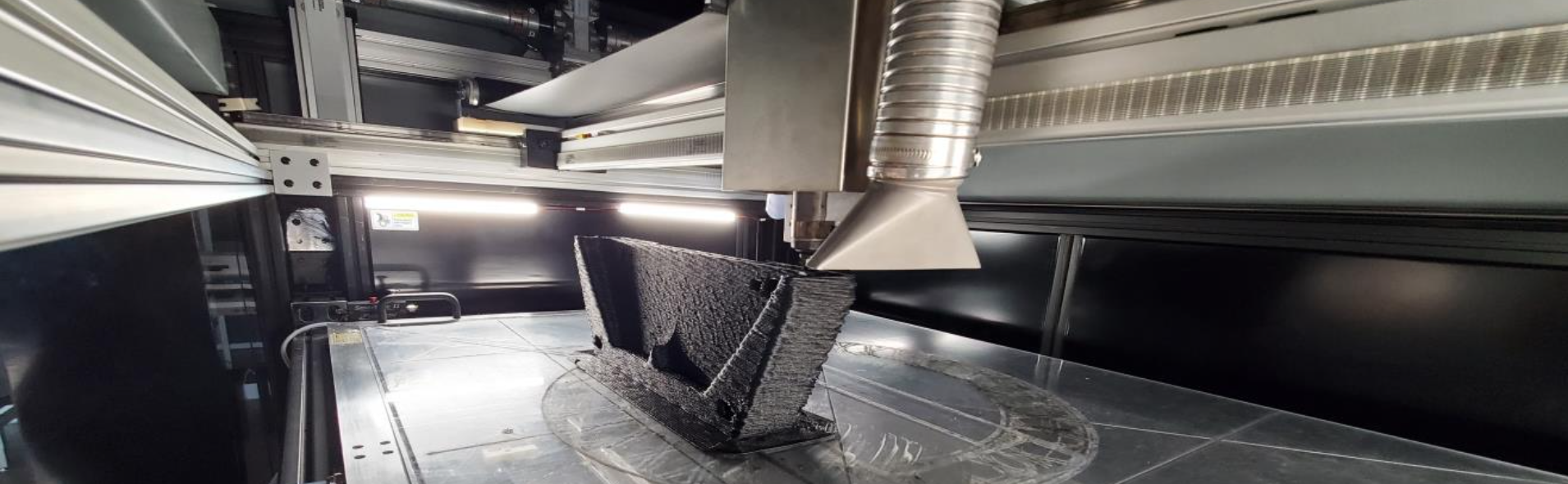

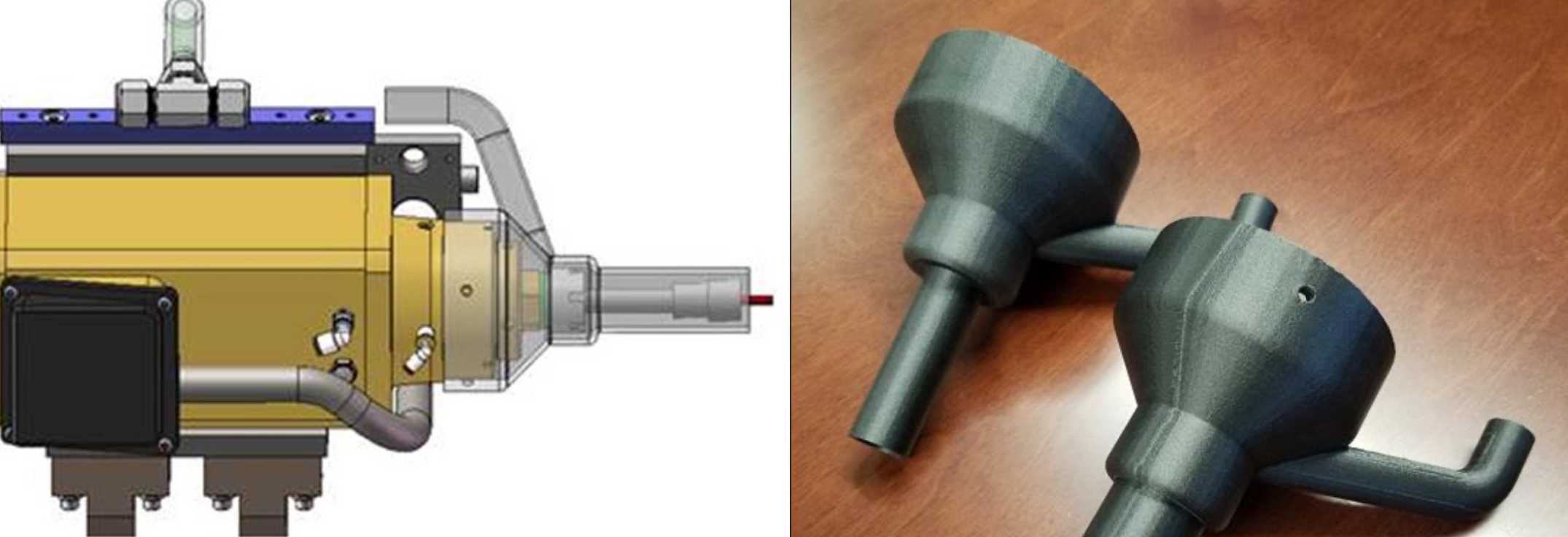

JuggerBot 3D produces large-format machines equipped with state-of-the-art pellet extrusion technology for readily-available production materials and up to 200 times faster 3D printing.

Industrial grade 3D printing technologies for performance, reliability, and value.

JuggerBot 3D's additive systems are material-agnostic and standalone systems, complete with built-in dryers, contained loading bays, and environmentally controlled build chambers that promote adequate layer adhesion and cooling.

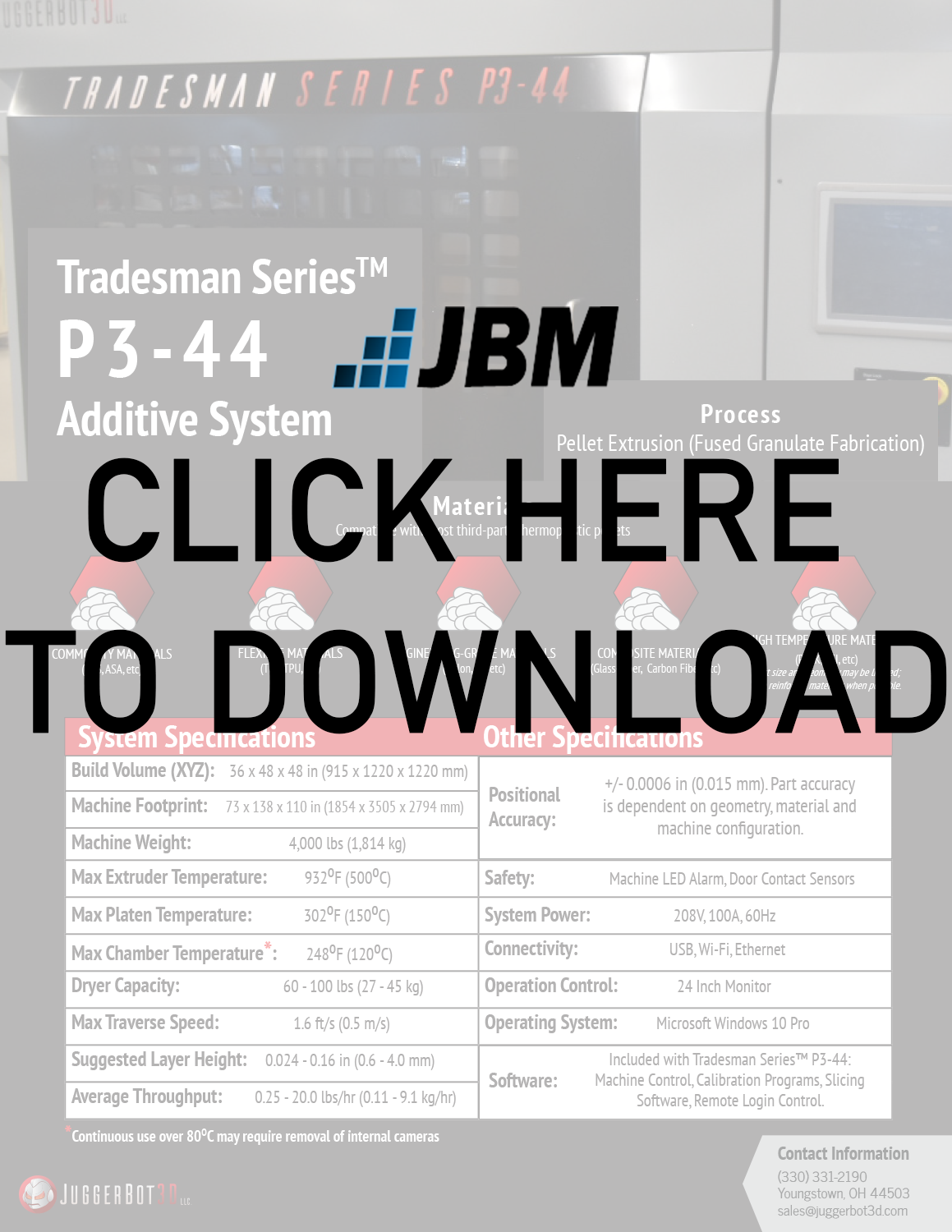

P3-44

-

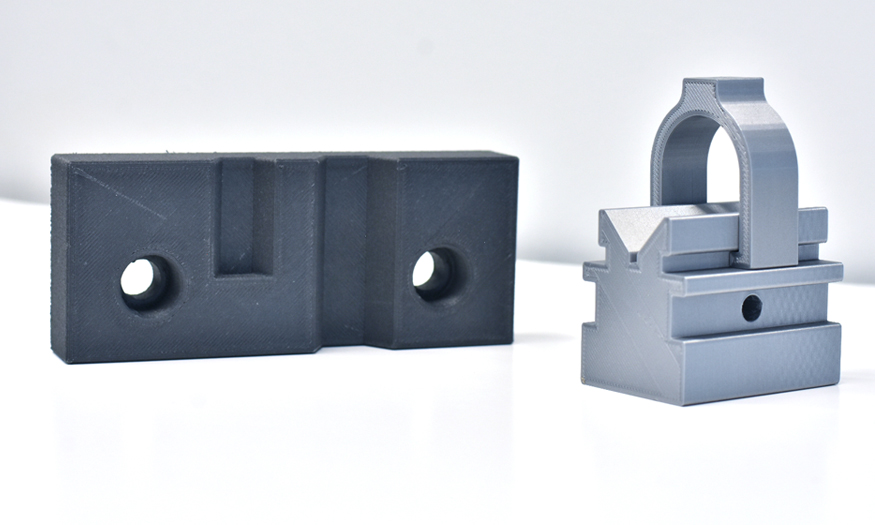

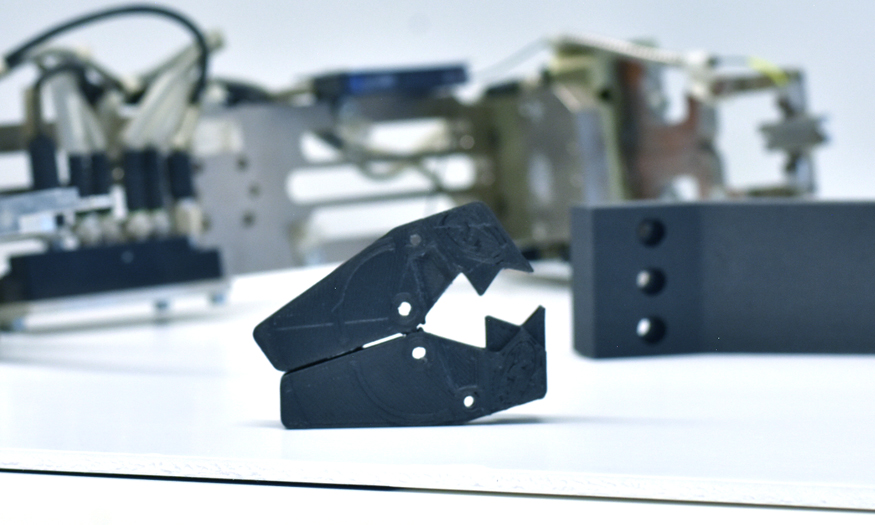

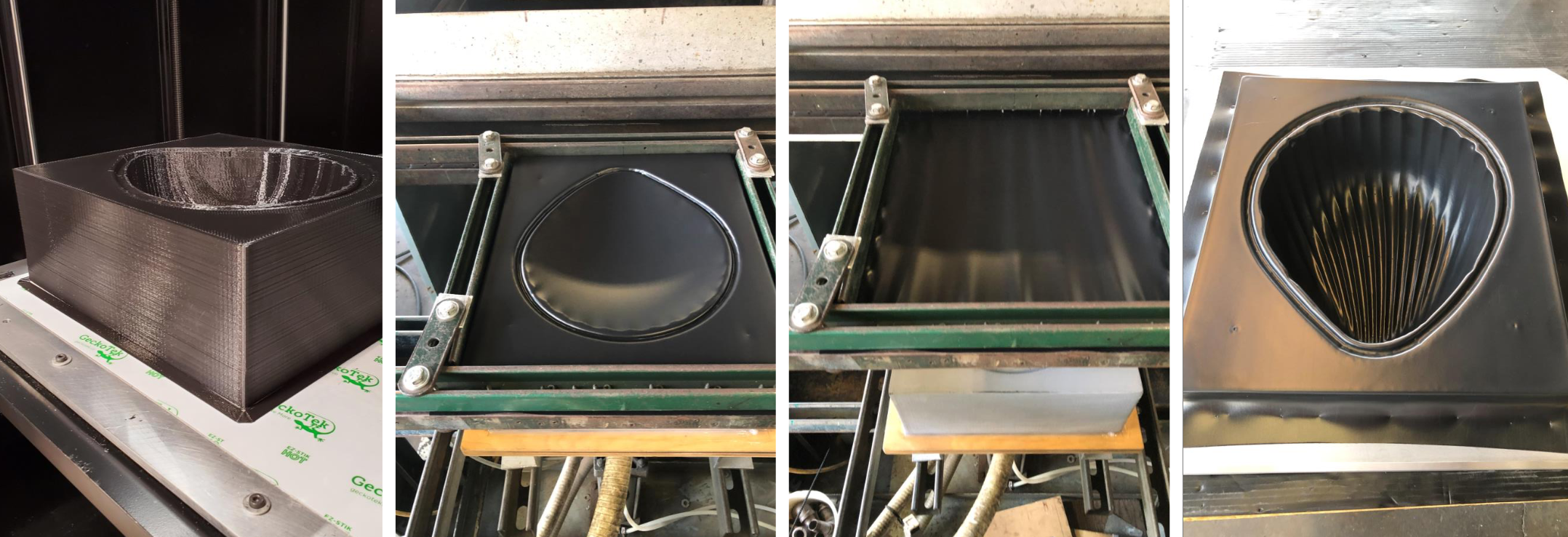

Using pellet extrusion technology to produce turnkey prototypes, tooling, and production parts.

-

Impressive material throughput ranging from 1lb/hr to 20lbs/hr, depending on printer size.

-

Max traverse speed of 3.3 ft/s.

Request for Parts

Not sure if JuggerBot 3D's printers are right for your shop? You can request a print quote here and see your printed part in person to help make your decision. Just follow the material and process guidelines.

Tooling & Product Applications

-

Machine Guarding / End Effectors

-

High Temperature Vacuum Molds

-

Non-Pneumatic Tires

Website: JuggerBot 3D

Description: Industrial 3D Printing Technology